The Slurry SpreaderTM is a patented attachment for ready mixed concrete truck chutes that allows uniform application of cement slurry to soils and aggregates, for modification or stabilization, without generating any cement dust. After the cement slurry is mixed into the soil or aggregate and the treated material is compacted and cured, the new layer exhibits increased strength and significantly improved resistance to moisture and frost damage. Application of cement slurry using the Slurry SpreaderTM is especially beneficial in pavement reconstruction, including full-depth reclamation of asphalt pavements, in urban areas where cement dust must be eliminated.

Slurry

Cement slurry is a mixture of portland cement, water, and sometimes mineral and/or chemical admixtures that is produced at a concrete batch plant and delivered to a job site in a ready mixed concrete truck. Slurry is easily applied to soils and aggregates using a Slurry SpreaderTM attached to the end of a truck chute. The slurry application rate is determined based on the desired cement concentration, thickness, and density of the treated layer and the composition of the slurry. After application, the slurry is immediately mixed into the soil or aggregate to a specified depth and compacted to the desired density. Following grading to ensure appropriate elevations and slopes, the cement-treated layer is cured in a moist condition for a specified period of time to ensure continued cement hydration, which is a chemical reaction that leads to increased strength and durability of the layer.

Use of cement slurry completely eliminates all cement dust, which is especially important in urban areas. Contractor personnel and individuals working or residing at adjacent properties are not exposed to dangerous levels of crystalline silica typical of cement dust, adjacent properties are not contaminated with cement dust, and drivers in adjacent traffic lanes are not subjected to visibility problems from cement dust, even in windy conditions.

Products

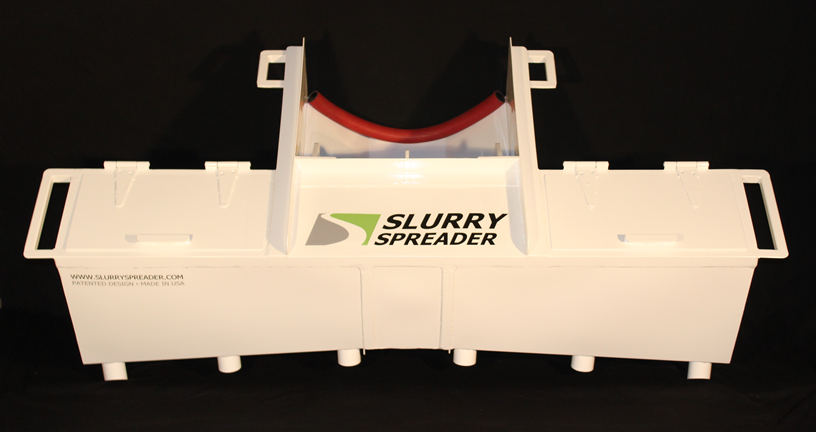

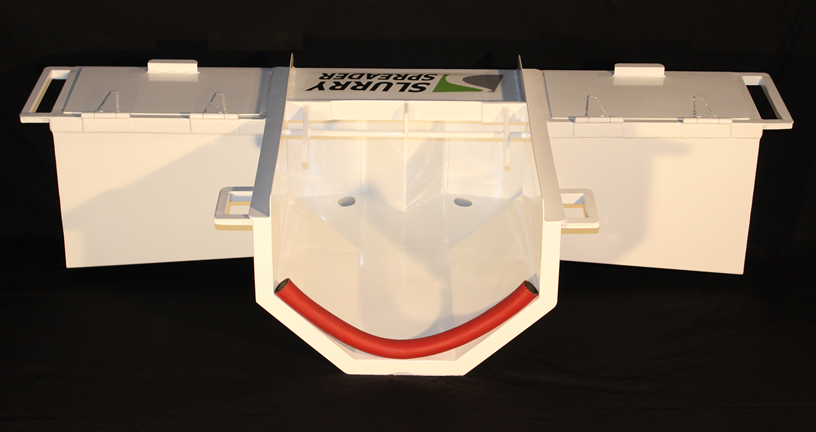

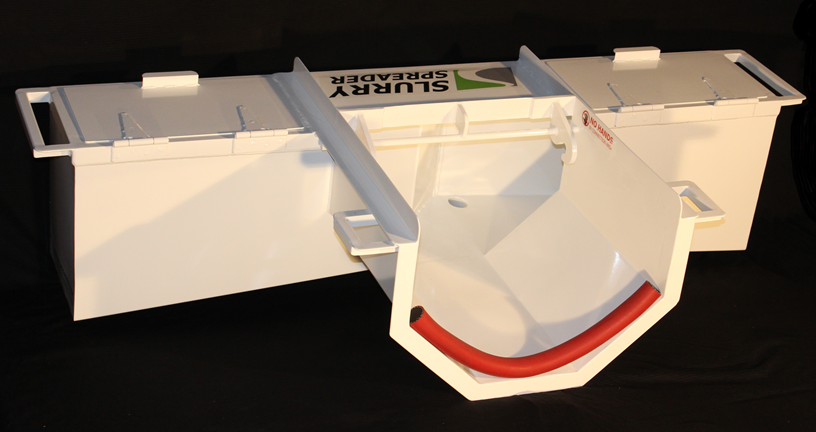

The patented design of the Slurry SpreaderTM ensures improved uniformity of cement slurry application. The engineered basin design moves the slurry quickly to all nozzles, and attachment to the end of a ready mixed concrete truck chute enables a high degree of maneuverability on the job site for working along curves and around utilities or other obstacles.

The durable steel construction of the Slurry SpreaderTM is complemented by a primed and powder-coated finish, and large lids with heavy-duty hinges provide excellent access for cleaning the interior of the basin during and after use. The lightweight design and conveniently positioned handles allow two persons to easily pick it up. The Slurry SpreaderTM is available for both front-discharge and rear-discharge ready mixed concrete trucks. The Slurry SpreaderTM is designed and built in the USA.

Please call +1-385-204-5085 or use the contact form to inquire about pricing and availability.

Resources

Slurry SpreaderTM User’s Guide – Coming Soon

Slurry Application Rate CalculatorAbout

Slurry Spreader, LLC is a manufacturing company headquartered in Provo, Utah, that specializes in production of the patented Slurry SpreaderTM for both front-discharge and rear-discharge ready-mixed concrete trucks. Having more than 20 years of experience in the pavement and materials engineering field, personnel at Slurry Spreader, LLC are able to address all aspects of Slurry SpreaderTM use for both modification and stabilization of soils and aggregates for construction of pavements, building pads, and similar projects.